Introduction:

In the world of customization and printing, cold transfer printing has emerged as a revolutionary technique that offers unparalleled versatility and quality. Whether you’re a DIY enthusiast, a small business owner, or a large-scale manufacturer, cold transfer printing can transform the way you create and customize products. In this blog, we’ll dive into what cold transfer printing is, how it works, and why it’s becoming the go-to method for many industries.

What is Cold Transfer Printing?

Cold transfer printing, also known as cold peel transfer printing, is a method where designs are printed onto a special transfer paper and then transferred onto various surfaces using heat and pressure. Unlike traditional heat transfer methods, cold transfer printing doesn’t require high temperatures, making it suitable for a wider range of materials, including heat-sensitive fabrics like polyester and spandex.

How Does It Work?

- Design Creation: The process begins with creating a design using graphic design software. This design is then printed onto a special transfer paper using sublimation inks or other compatible inks.

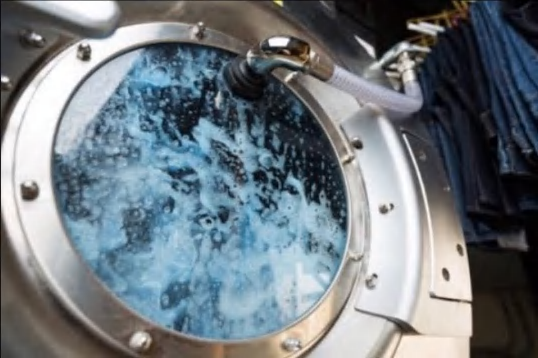

- Transfer Process: The printed transfer paper is placed onto the substrate (the material you want to print on). A heat press is used to apply pressure and a moderate amount of heat, which activates the ink and transfers the design onto the substrate.

- Peeling: After the transfer is complete, the paper is peeled away while still warm or cold, depending on the specific method. This reveals the vibrant, high-quality design on the substrate.

Advantages of Cold Transfer Printing:

- Versatility: Cold transfer printing can be used on a wide range of materials, including fabrics, ceramics, metals, and more.

- Durability: The prints are highly durable and resistant to washing, making them ideal for clothing and textiles.

- Vibrant Colors: The process allows for high-resolution prints with vibrant colors and fine details.

- Eco-Friendly: Since it requires less heat and energy, cold transfer printing is considered more environmentally friendly compared to traditional methods.

Applications of Cold Transfer Printing:

- Apparel: Custom t-shirts, sportswear, and fashion garments.

- Home Decor: Custom pillows, curtains, and upholstery.

- Promotional Products: Mugs, phone cases, and tote bags.

- Industrial Uses: Labels, tags, and branding on various products.

Conclusion:

Cold transfer printing is a versatile, durable, and eco-friendly method that is revolutionizing the customization industry. Whether you’re looking to create personalized apparel, unique home decor, or promotional products, cold transfer printing offers a high-quality solution that meets the demands of modern consumers. Embrace the magic of cold transfer printing and unlock endless possibilities for your creative projects!

Ready to explore the world of cold transfer printing? Share your thoughts and experiences in the comments below, and don’t forget to subscribe for more tips and tricks on customization and printing!

Dongguan TuoPu Apparel Co.,Ltd

The Magic of Cold Transfer Printing

One response

This is such an informative post! I’ve been experimenting with cold transfer printing for my small custom apparel business, and the results have been incredible. The vibrancy of the colors and the durability of the prints are unmatched. I especially love how it works on heat-sensitive fabrics—it’s been a game-changer for my polyester activewear line. Thanks for breaking down the process so clearly! Can’t wait to try more projects with this technique.